Product added to cart

F4629

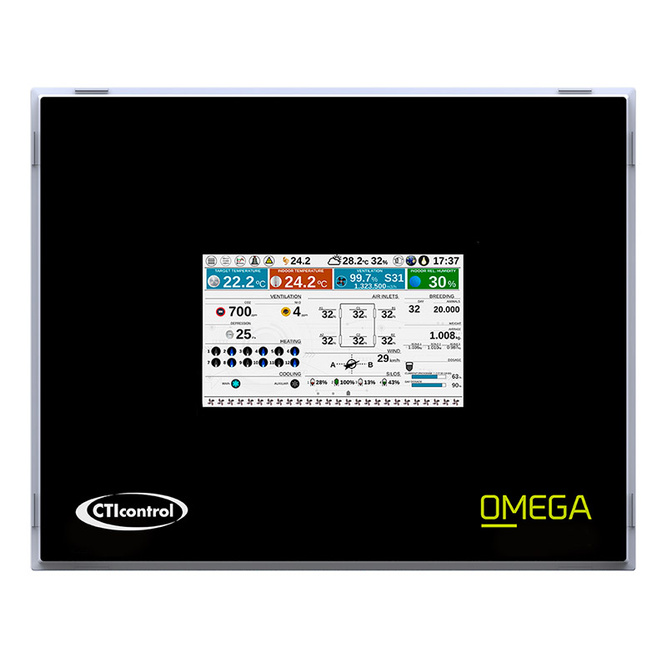

OMEGA production computer with curves, statistics, vacuum, CO2 and ammonia measurement, poultry scales and under silo

€6,908.85

Advanced OMEGA production computer dedicated to controlling the production process in a livestock building. It is perfect for poultry farms, pigs, rabbit houses, as well as other buildings of industrial animal husbandry. Extensive functions of the controller allow you to manage the operation of the ventilation, heating, cooling system, lighting. Thanks to the set curves, the breeder has the opportunity to easily control the production process. The controller also has the function of monitoring bird weight gains from 4 weights and feed control from 3 silos. Extensive relay inputs allow sensors to be connected to control temperature, internal humidity andexternal, vacuum, ammonia, CO2. The production computer is easy to use thanks to the clear, colorful and touch display. It has a built-in wi-fi input that allows the controller to be connected to the CT1 communication module. This type of driver synchronization allows you to manage the farm from anywhere. Data Collected in the Omega controller they are saved and subjected to statistics, and they can be exported. Main features:

Fast shipping

14 days for return

Over 500,000 satisfied customers

Availability

Available on request

Advanced OMEGA production computer dedicated to controlling the production process in a livestock building. It is perfect for poultry farms, pigs, rabbit houses, as well as other buildings of industrial animal husbandry. Extensive functions of the controller allow you to manage the operation of the ventilation, heating, cooling system, lighting. Thanks to the set curves, the breeder has the opportunity to easily control the production process. The controller also has the function of monitoring bird weight gains from 4 weights and feed control from 3 silos. Extensive relay inputs allow sensors to be connected to control temperature, internal humidity andexternal, vacuum, ammonia, CO2. The production computer is easy to use thanks to the clear, colorful and touch display. It has a built-in wi-fi input that allows the controller to be connected to the CT1 communication module. This type of driver synchronization allows you to manage the farm from anywhere. Data Collected in the Omega controller they are saved and subjected to statistics, and they can be exported. Main features:

Dimensions:

500x390x210 mmWrite Your Own Review